Today I decide to make firmware (ROM) update, after finishing and restarting Android i get information about “Invalid IMEI”.

When my heart start beating again i start looking out for solution then develop many attempts to address the problem.

RT4 is unpopular phone, so there virtually none information.

Lucky chipset inside phone is compatible with Xiaomi solution and that software i used.

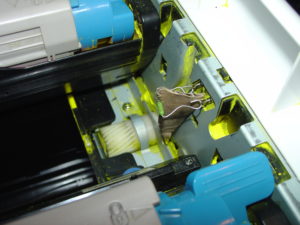

- open Your phone, and on back label You have IMEI numbers for two sim cards – write them down.

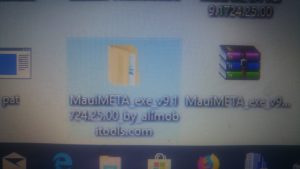

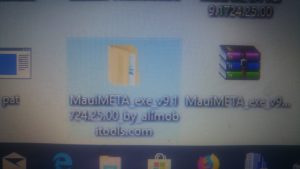

- using windows computer install https://allmobitools.com/downloading-maui-meta-3g-4g-imei-repair-tool/

- after install open application using administrator privilege

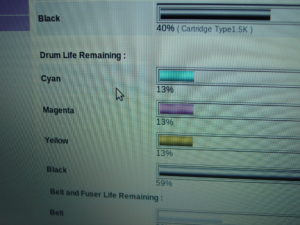

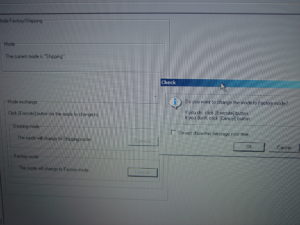

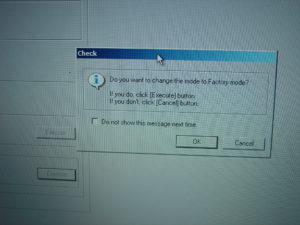

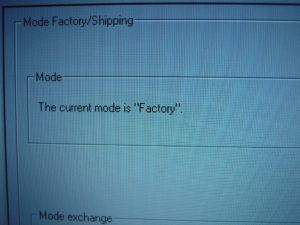

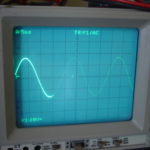

on right side click “reconnect” remove battery and unplug usb cable, install battery, plug usb cable there should be beep of plugging in usb device, after while You should see something like this:

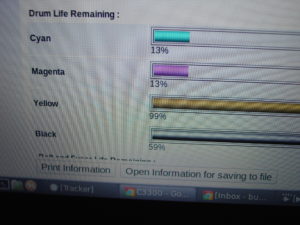

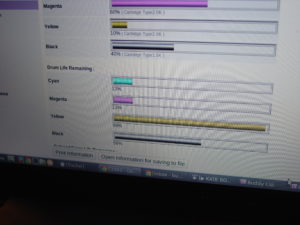

- from drop down menu on the left select “IMEI DOWNLOAD” and in new window click button “IMEI UPLOAD FROM FLASH”

They should appear two tabs SIM1 SIM2

You need to enter Your IMEI form point 1

last digit is checksum so don’t enter it, it will be calculated automatically, if it match then You are good to go and can click “Download to flash”

After successfully write, click disconnect and restart phone, it should work properly 🙂